| Face Grinding | Top Grinding | Flank Grinding |

|

|

|

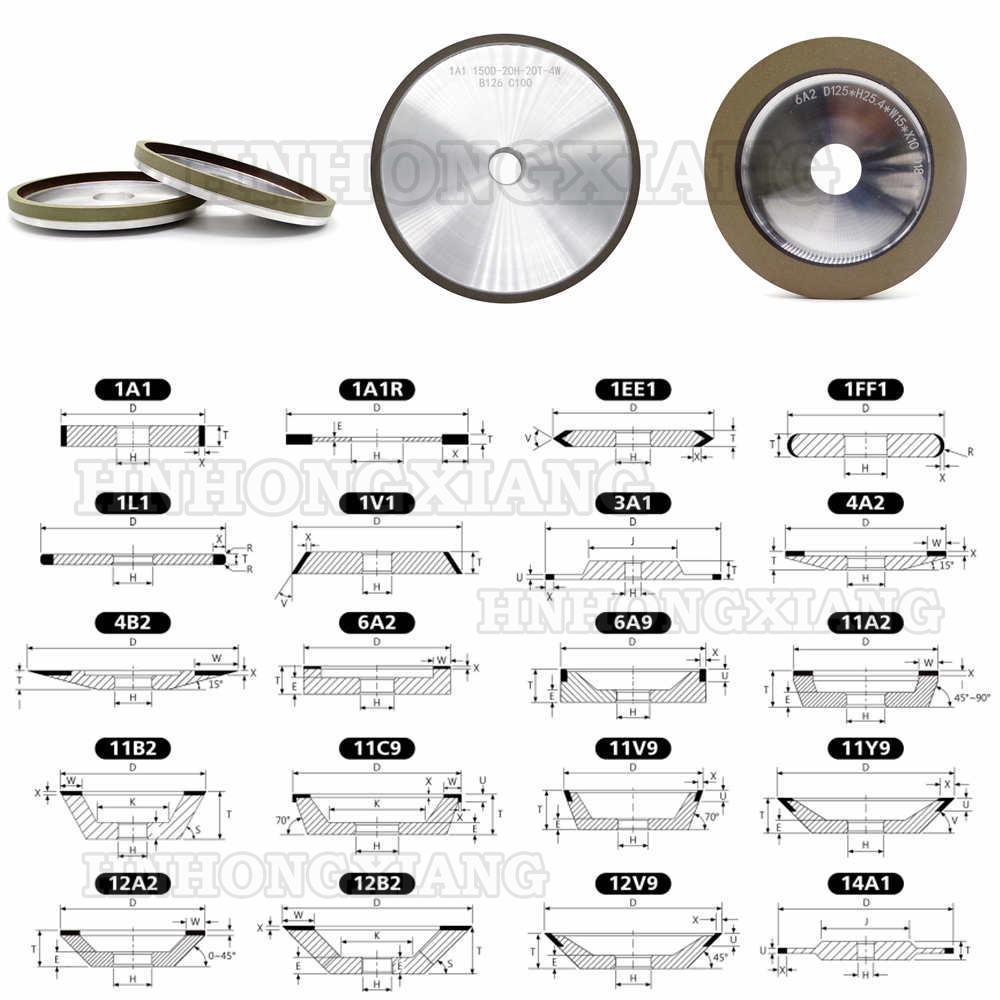

| 4A2, 4V2, 12V2, 12V9, 12A2, 4B2, etc | 4A2, 6A9, 12A9, 14AA1, 14A1, 14M1, 14B1, 3M1, 4B1, 11V9, 12V2, 12V9, etc | 4A9, 3A1, 1A1, 11A2, etc |

* Grinding Pins for Hollow-tooth Saw Blade: 1A1W, 1A8W

| Resin Bond Diamond Wheels for Grinding Woodworking Carbide-tipped Circular Saw Blades | ||||

| Grinding Area | Shape | Size | Mesh | Shape Drawings |

| Tooth Face Grinding |

4A2 | D100/125*T10*H20*X5*U2 | D170/200 D230/270 DoubleGrit: 180# 400# |

|

| 4V2 | D100*T12*H32*X3*U2 | D170/200 D230/270 |

|

|

| 12V2 | D125/150*T13*H32*X2*U2 | D200/230 D230/270 D325/400 |

|

|

| 12A2 | D125/150*T13*H32*X2/4*U2 | D200/230 D230/270 D325/400 |

|

|

| Grinding Pins | 1A1W | D6.5/7*L45*T6*I12*U35 | D200/230 |  |

| Tooth Tops Grinding |

4A2 | D100*W4*X3*H25 | D46/D64 |  |

| 14B1 | D127*U5*X7*V15*H32 | D46/D54/ D107/D126 |

|

|

| 14A1 | D150*U5*X8*H32 | D64 |  |

|

| 14M1 | D150*U5*X8*U2.5*V5°*H32 | D46/D107 |  |

|

| Flank Grinding |

3A1 | D100*T14*H32*X6*U4 | D140/170 D325/400 |

|

| 1A1 | D125*W8*X15*H20 | D64 |  |

|

| 11A2 | D75/100*W4-6*T3-5 | #100 - 230 #300 - 600 |

|

|

| Types and sizes of resin diamond wheels are can be customized. | ||||