Resin bond diamond grinding wheel is composed of the diamond layer and aluminum matrix. The diamond layer contains mixed powder of diamond powder, resin powder and metal powder, as well as resin binder pressed filler. When the aluminum substrates are combined, the outer circle, inner circle, and plane of the hard alloy and other workpieces are roughed, semi-finished, and finely ground with diamond grinding wheels during high-speed operation.

Feature:

· Selection of high-quality artificial diamond powder and imported raw materials.

·Good self-sharpness, high grinding efficiency and long working life.

·The grinding wheel has a certain elasticity, which is conducive to improving the roughness of the surface of the working layer.

·Shorter production cycle time; higher removal rate, easily to make complex wheels.

Tungsten steel grinding wheel is recommended to use diamond resin grinding wheel

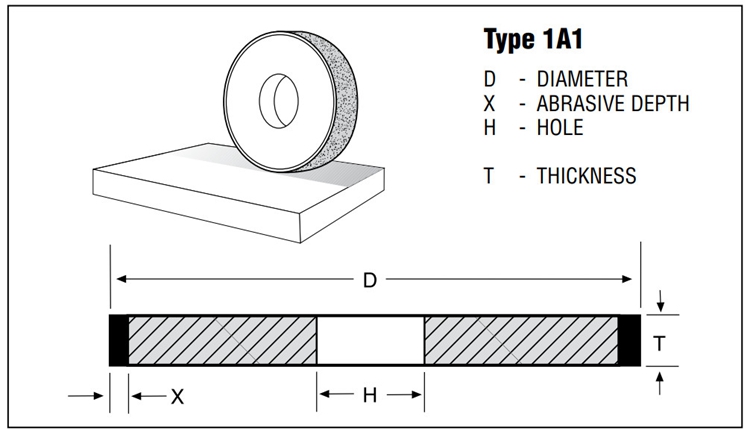

(model, grinding purpose, specification)

12V2 alloy cutting tool grinding--100D*32T*20H*5W*5X

14A1 Tungsten steel cylindrical grinding--400D*30T*203H*15U*5X

1A1 Centerless tungsten steel guide plate grinding--150D*10T*31.75H*5X

1A1 Tungsten steel plane grinding--180D*10T*31.75H*5X

1A1 Tungsten steel plane grinding--350D*30T*127H*10U*5X

1A1 Tungsten steel centerless grinding--300D*100T*120H*8X

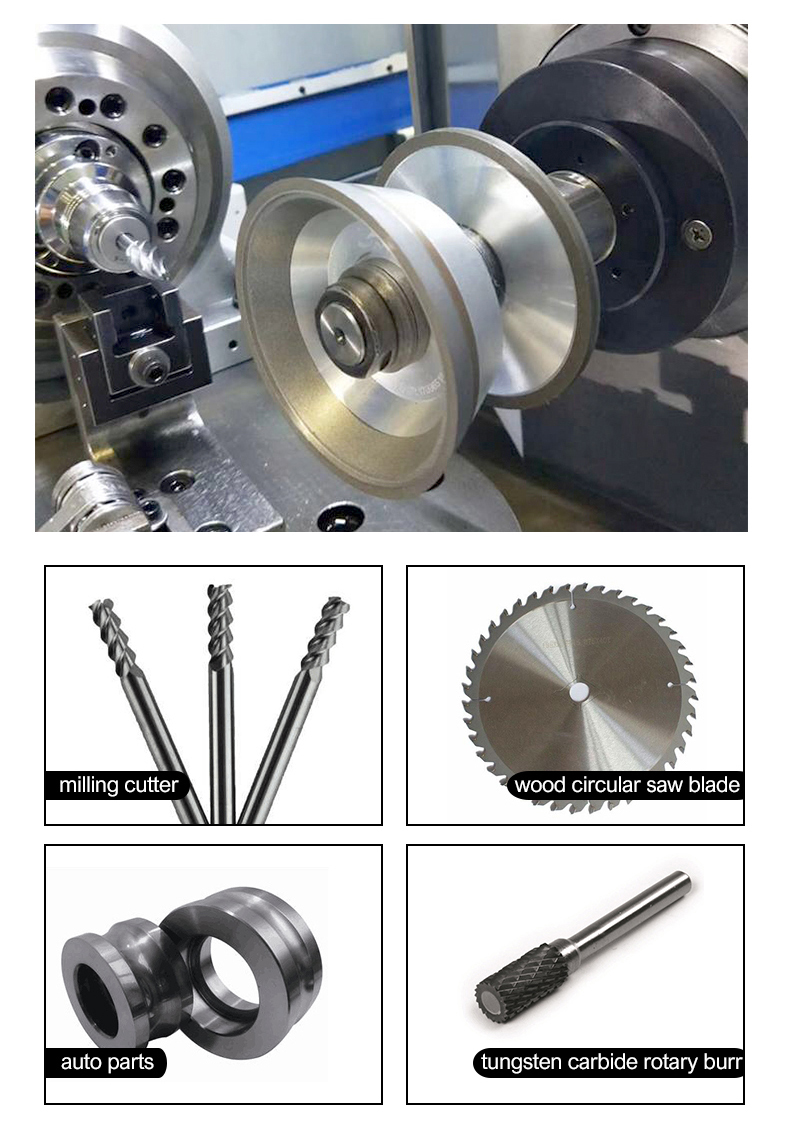

1. Parallel resin diamond grinding wheel: mainly used for cylindrical grinding and blade machining of cemented carbide;

2. Parallel arc resin diamond grinding wheel: mainly used for forming grinding of cemented carbide and forming grinding of arc surfaces;

3. Double-sided concave resin diamond grinding wheel: mainly used for grinding measuring tools and coreless grinding wheels;

4. Double bevel resin diamond grinding wheel: mainly used for forming grinding of carbide gear hobs and thread cutters;

5. Bowl-shaped resin diamond grinding wheel: mainly used for the sharpening of cemented carbide tools and high-speed steel tools, and can also be used for milling.