Ni Coated Diamond Powder |

TI Coated Diamond Powder |

Electroless Ni Coat / Electrolytic Ni Coat |

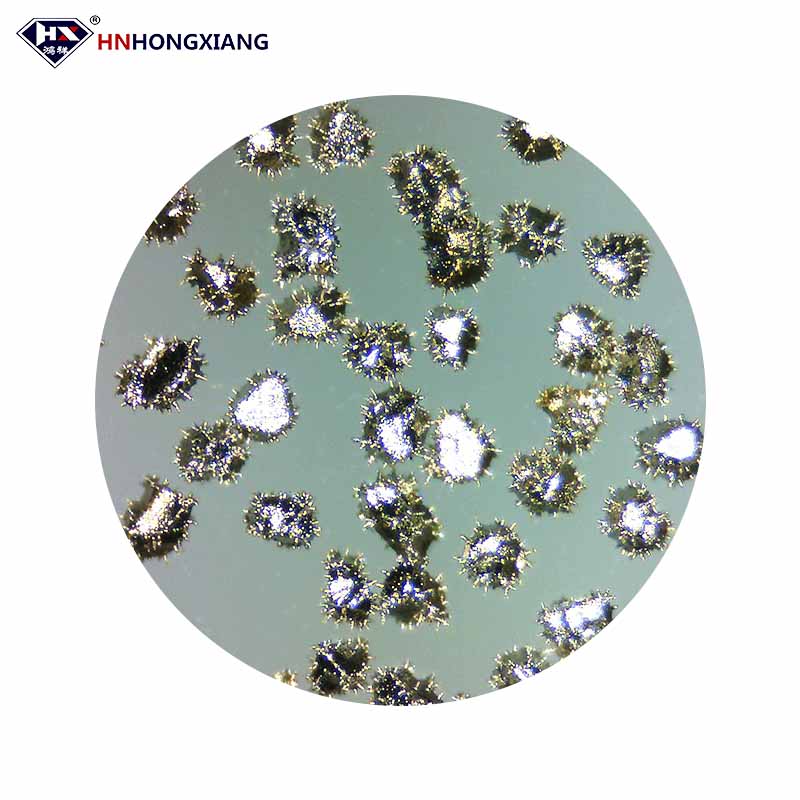

Ti coated diamond |

| Nickel-plated diamonds are generally divided into two categories:ordinary nickel plating and electroless nickel plating,according to the weight of nickel plating distinction,can be divided into 30%weight gain and 56% weight gain. |

Through forming a dense layer of titanium,the coating is able to avert the the erosion by metal powder and take effect of isolation protection at high temperature during the manufacture of diamond tools, avoid the diamond oxidation. Protect and maintain the diamond performance, prevent the diamond peeling off, prolong the tools work life.Ti-coated diamond is mainly designed for manufacturing the metal bond sintered diamond tools. |

30% NI Coated / 56% Ni Coated |

|

|

|

Application |

|

| 1.Ni coated diamond is mainly used in the manufacture of resin binder tools,such as used in cemented carbide,glass and ceramic grinding wheel, 2.Ni coated diamond can also be used in the manufacture of electroplated diamond grinding head, jewelry and other crafts for the carving and so on, 3.Ni coated diamond powder is mainly used in the manufacture of diamond cutting wire saws and grinding tools for plastic,silicon and glass processing, 4.Ni coated diamond can also be used in the electrical and electronic industry in the graphite, carbon material cutting and other materials. |

Ti coated Diamond is mainly used in the macture of metal bonding tools,such as stone tools,diamond bits, saw blades,drill bits. |

|

|

| Mesh | Electroless Ni Coat | Electrolytic Ni Coat | Ti Coat |

| 30/40 | * | * | |

| 40/50 | * | * | * |

| 50/60 | * | * | * |

| 60/80 | * | * | * |

| 80/100 | * | * | * |

| 100/120 | * | * | * |

| 120/140 | * | * | * |

| 140/170 | * | * | * |

| 170/200 | * | * | * |

| 200/230 | * | * | * |

| 230/270 | * | * | * |

| 270/325 | * | * | * |

| 325/400 | * | * | * |

| 400/500 | * | * | * |