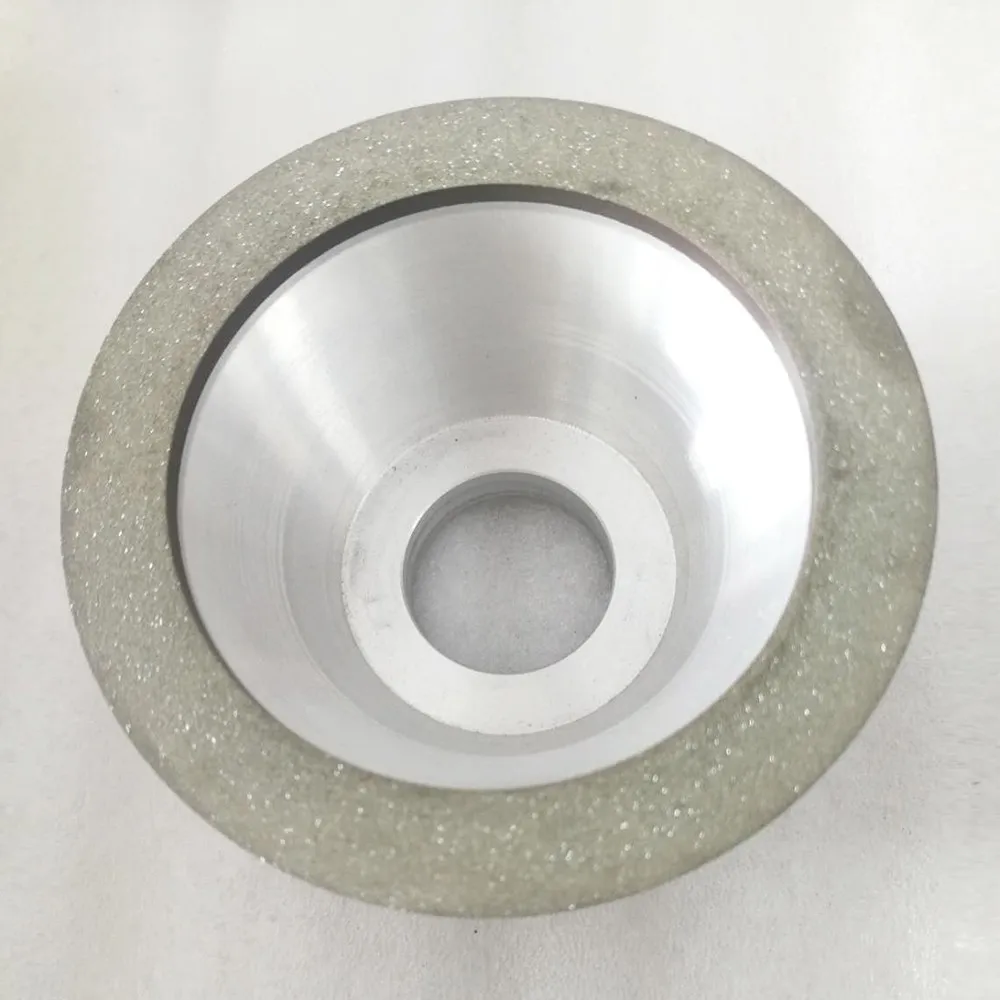

The diamond grinding wheel is made of the synthetic diamond as the main abrasive. It has high hardness, high strength, and strong grinding ability. It is used for grinding high and hard alloys, non-metallic materials, cutting hard and brittle hard alloys, non-metallic minerals and so on. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, and other high-hard and brittle materials and special materials processing.

1.PCD, PCBN, Precision grinding of ceramic tools

2.Hard Alloy cermet cutting tool for efficient grinding

3. Woodworking saw blades, band saws, milling cutters, drill bits, etc.

4.Monocrystalline silicon, high precision electronic glass precision high-quality processing

5.Processing of mechanical parts such as cast iron, hard steel, and stainless steel

Depending on the size, flat-shaped reinforced grinding wheels are used for cylindrical grinding, internal grinding, surface grinding, centerless grinding, tool grinding, thread grinding and grinders.

| GRIT SIZE | O/D | CONCENTRATE | SPECIFICATION |

SDC170 |

150D | 100% | 80D-8T-5X-31.75H |

| 150D | 100% | 100D-6T-5X-31.75H | |

| 150D | 100% | 150D-6T-5X-31.75H | |

| 150D | 100% | 150D-8T-5X-31.75H | |

| SDC200 | 150D | 100% | 150D-10T-5X-31.75H |

| SDC230 | 150D | 100% | 150D-10T-10X-31.75H |

SDC400 |

150D | 100% | 150D-6T-5X-31.75H |

| 150D | 100% | 150D-8T-5X-31.75H | |

| 150D | 100% | 150D-10T-5X-31.75H | |

| 150D | 100% | 150D-10T-10X-31.75H | |

| SDC100 | 150D | 100% | 150D-10T-5X-31.75H 150D-10T-10X-31.75H |

| SDC120 | 150D | 100% | |

| SDC140 | 150D | 100% | |

SDC600 |

150D | 100% | 150D-10T-5X-31.75H |

| 150D | 100% | 150D_10T-10X-31.75H | |

| SDC800 | 150D | 100% | 150D-10T-5X-31.75H |

| SDC170 | 200D | 100% | 200D-10T-5X-50.8H |

| SDC200 | 200D | 100% |

1. The above is part of the size of the grinding wheel. Please contact us for other sizes.

2. Our factory can customize the production of flat, cup, bowl, dish, single bevel, double bevel, double-sided concave and other shapes and sizes of grinding wheels according to customer's drawings.

1. Diamond abrasive is relatively sharp, so the grinding wheel of the diamond wheel has higher grinding efficiency, and the grinding ratio of the ordinary grinding wheel is about 1:1000, and the wear resistance is relatively high.

2. The diamond resin grinding wheel has good self-sharpness, small heat generation during grinding, and is not easy to block, which reduces the phenomenon of work burns during grinding.

3. Diamond abrasive particles are uniform and very fine, so the diamond grinding wheel has high processing precision, and is mainly used for fine grinding, semi-finishing, knife grinding and polishing.

4. The diamond grinding wheel can almost achieve dust-free processing, meeting the requirements of modern industry for environmental protection.