DETAILS:

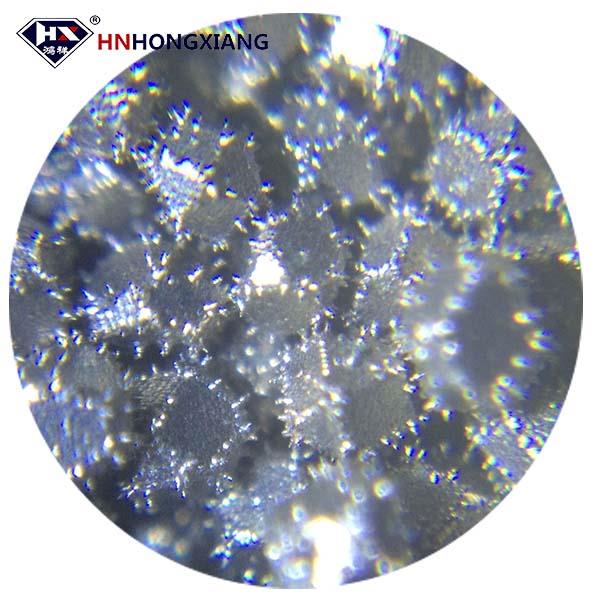

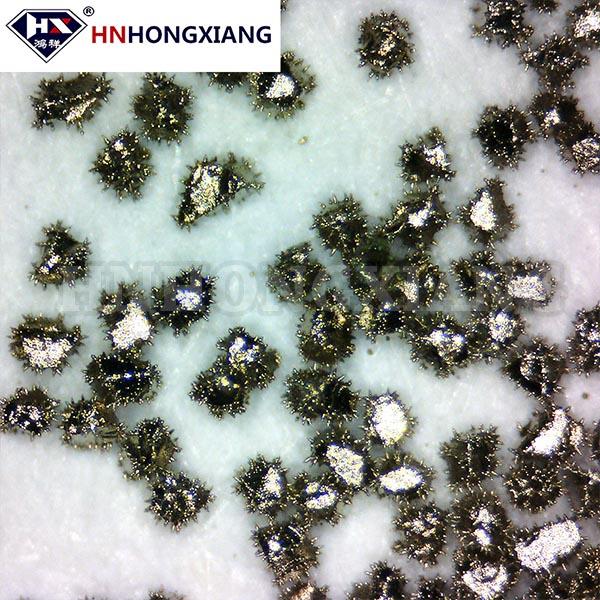

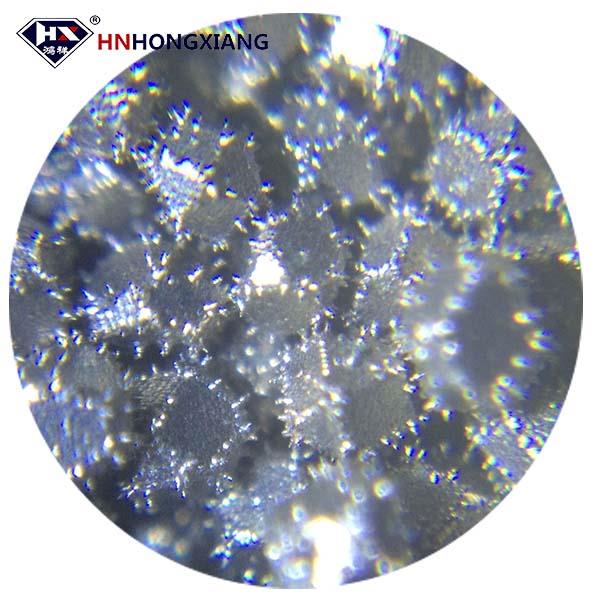

Nickel-plated diamond is a layer of nickel plated on the diamond surface. It has a spiky protrusion and is suitable for the production of resin bond products. The burr-like surface is convex and the structure significantly improves the holding power between the diamond abrasive and the bonding agent. Avoid premature diamond shedding during use, increase diamond usage, and effectively extend product life.

Plated diamond, also known as diamond coated or plated diamond, the diamond surface is coated with a layer of metal diamond gives many new features, in order to improve the diamond and matrix interfacial bonding ability, holding force and strength, reduce the thermal shock, protection against oxidation and graphitization of diamond, reduce the degree of thermal damage of diamond. To extend the service life of the product. The metal is nickel and titanium and alloy plating method commonly used ordinary plating and electroless plating two, weight method is usually 30% and 56%, in addition, can also according to the actual situation and the requirements of customers customized. General for nickel plated diamond and diamond coated diamond.

|

Nickel plated diamond powder |

||||||||

|

30/35 |

35/40 |

40/45 |

45/50 |

50/60 |

60/70 |

70/80 |

80/100 |

100/120 |

|

120/140 |

140/170 |

170/200 |

200/230 |

230/270 |

270/325 |

325/400 |

400/500 |

|

APPLICATION SCOPE:

Mainly used for resin binder tools. it is widely used in the manufacture of metal bond and resin bond tools, such as knives, grinding wheels, saw blades and drills.

With the development of science and technology, the use of nickel coated diamond diamond wire cut sapphire wafer manufacturing more widely used.

DETAILS:

Nickel-plated diamond is a layer of nickel plated on the diamond surface. It has a spiky protrusion and is suitable for the production of resin bond products. The burr-like surface is convex and the structure significantly improves the holding power between the diamond abrasive and the bonding agent. Avoid premature diamond shedding during use, increase diamond usage, and effectively extend product life.

Plated diamond, also known as diamond coated or plated diamond, the diamond surface is coated with a layer of metal diamond gives many new features, in order to improve the diamond and matrix interfacial bonding ability, holding force and strength, reduce the thermal shock, protection against oxidation and graphitization of diamond, reduce the degree of thermal damage of diamond. To extend the service life of the product. The metal is nickel and titanium and alloy plating method commonly used ordinary plating and electroless plating two, weight method is usually 30% and 56%, in addition, can also according to the actual situation and the requirements of customers customized. General for nickel plated diamond and diamond coated diamond.